Father/daughter Team Tackles Sustainable Carbon Venture

How one Southern startup recycles farm waste to purify water, build green, and generate power.

As an entrepreneur running a business incubator in the Memphis area, Bryan Eagle knew nothing about the organic charcoal product known as biochar. He wasn’t alone, as the material made from plant waste occupies an obscure niche in agricultural communities and isn’t widely used in the U.S. However, the modernization of an ancient technique has opened up a world of possibilities, and biochar is poised to take off as the green solution to a slew of 21st-century problems.

Biochar is a stable carbon material made from plant-based biomass. Far from a new concept, biochar is as old as agriculture itself. Indigenous people have effectively added burned organic waste to fields for millennia, but the idea that biochar could be perfected for industrial uses and to mitigate climate change has been around for less than 20 years.

Bryan says he first ran across biochar through a nonprofit venture focused on leveraging technologies from the local university network in Memphis. “The professor who created this approached me, and I knew nothing about clean tech, ag waste, or biochar. But the more I read about it, the more excited I became about the potential,” he said. “We saw early on that this could be a powerful tool in addressing climate change, not just in our business but on a global basis, that’s very quick, very low-cost.”

Bryan’s company, Glanris, now produces a designer Biocarbon that functions as everything from a soil amendment to a filler in asphalt, concrete, drywall, and a filter for air and water. Unlike traditional biochar products made from waste wood, Glanris has a sustainable and locally grown raw material supply of rice husks.

“We started this journey in 2019 to look at what we can do with all the ag waste generated across the river in Arkansas,” Bryan said. He approached Riceland Foods, the largest rice producer in the state, to find a way to repurpose their waste material. “There are 60-acre landfills that are being filled up with rice hulls,” he said, “so we set up to try to find a greener alternative.”

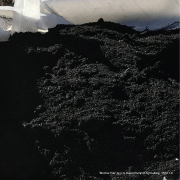

Glanris superheats the husks using a process called pyrolysis, which removes combustible gasses in the absence of oxygen and seals carbon into blackened biochar granules. Instead of plant material burning or rotting and being released into the atmosphere as CO2, biochar stabilizes the carbon content so it doesn’t break down. The pyrolysis units pump out a patented Biocarbon product resembling coal-black shards of confetti, which is packaged in 300-pound “Supersacks” or smaller boxes and shipped all over the globe.

“The rice mills are paying $12-20 per ton to haul this stuff away,” Bryan said. If you can instead turn it into products that give you heat, electricity, and water filtration, we make more selling our biocarbon into the environmental remediation market than they do from the rice.”

Follow the green

As founder and CEO, Bryan started small while thinking big. One shrewd move was to make his new company a family affair. When his daughter Anastasia Eagle returned to the South, her business and PR skills were quickly put to use at Glanris.

“When we first started the company, we were a two-person operation. That’s startup life. We’ve worn many hats on our heads, we’ve been able to do it all,” she said. “Now that we’re able to expand and grow, I am getting more back into the marketing side.”

Anastasia is thankful to be part of something that will help the region and community she cares about so much.

Bryan’s billion-dollar question is, “What does it take to get the funding you need to get this industry to scale?”

Bryan says the keystone of biochar’s economics is securing a long-term revenue stream that includes research, development, and application funding in the Farm Bill.

The National Center for Appropriate Technology (NCAT) is asking Congress to invest in biochar research to provide more insight into its larger-scale applications through the next Farm Bill under the bipartisan Biochar Research Network Act. If passed, the bill will authorize the U.S. Department of Agriculture (USDA) to establish a national-scale research program to test different biochar types in different soils and circumstances. With better research will come innovation and practical tools for farmers, ranchers, foresters, and businesses to lean into biochar as a climate solution.

“Hopefully, it will reach a critical mass where we can survive without subsidies, but it’s still needed,” he said. “Without support in the farm bill, the biochar industry would all but dry up. Biochar has so much potential to impact other areas, but we need to buy time to get into these markets.”

Making the move

After several years in the biochar business, he concluded that the only way to make money is to maximize carbon credits and take advantage of all possible revenue streams, which means using biochar in water systems, construction, and power generation in addition to ag uses.

That’s part of why Bryan and his employees decided to relocate the business to California. The state offers many green energy incentives, and there is a tremendous volume and diversity of forest and ag waste. Farmers can’t burn crop waste like nut shells or take them to landfills, so pyrolyzing is a great solution.

“There’s a huge demand for biochar in Sacramento Valley, and there are grants paying people to apply biochar as part of a remediation and soil improvement strategy,” he said. “Vineyards, orchards, row crops–farmers are trialing this stuff and finding out it has huge advantages.”

Glanris is making a last push to get funding for their $22M project in California, with $20M raised so far. The first phase in California is projected to produce 13,000 tons of biochar per year and generate 2.5 megawatts of electricity. “We’ve already got a 20-year power purchase agreement with a municipality that will sell [generated power] back to the grid,” Bryan said.

He believes green jobs are the jobs of the future, and the California project is expected to create around 20 jobs in its first phase that will pay at least double the prevailing wage for farm workers. As he grows this first instillation and expands to other cities in California, he hopes to create hundreds of green jobs.

Courtesy Soil Cycle

Courtesy Soil Cycle

Courtesy

Courtesy