Canva Pro

Canva ProEnergy Efficient Motors Toolkit

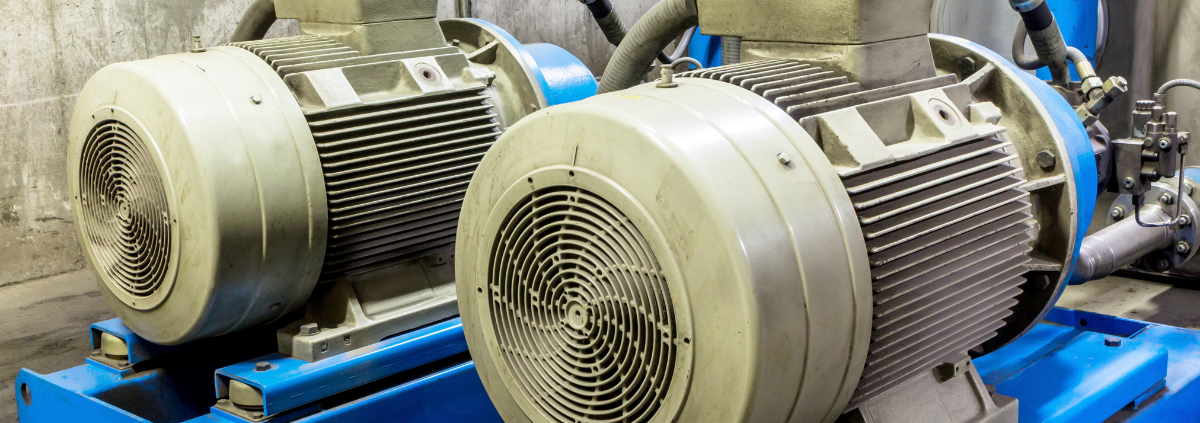

Pumps, Motors, Fans, and Aerators

Pumps, motors, fans, and aerators can use a lot of electricity. By upgrading and maintaining these pieces of equipment, you save energy and money while operating an efficient system.

The horsepower of the motor can be found on the nameplate, such as the one the photo below. This motor nameplate shows a HP (horsepower) of 250. And an efficiency of 95% at full load.

To following equation will help you determine the existing energy usage of your motor:

(Horsepower of the motor)*(.746 kwh/hp)/(Motor efficiency) = Kilowatts used by the motor

Where the motor efficiency is a decimal, not a percent.

For the motor in the photograph above, the energy usage of the motor is:

(255 HP)(.746 kw/HP)/.95 = 200.24 kilowatts

To determine the cost of the motor, multiply the energy usage of the motor by the hours of usage and then multiply this number the your energy cost per kilowatt-hour (kWh). For example, if you operate the motor in the photo 3,000 hours in one year, it will cost:

200.24 kW*3,000 hours * $0.08/kWh = $48,057.60

Efficiency Measures

Electronically commutated motors, also known as ECM, have no brushes, so they avoid the sparking and short life seen in brushed motors. They are more efficient because they have electronics that control the stator and do not need to waste power inducing the rotor field. This will reduce energy consumption directly by using less power to run the motor, and in air conditioning or refrigeration applications, there is less heat generation from the ECMs powering the fans.

You can install high-efficiency pumps and motors, as well as rewind older motors and rebuild older pumps if premium efficiency motors are too expensive. In the example above, a 95% efficient motor would costs: $48,057 in one year.

A 80% efficiency motor would cost:

(255 HP)(.746 kw/HP)/.80 = 237.79 kilowatts

237.79 kW*3,000 hours*$0.08/KWh = $57,069

That’s a difference of $9,012 per year. Installing a high-efficiency (95% efficient or greater) motor would clearly be a sound investment for the motor in this example.

Variable Frequency Drives

If the load on the motor, pump, or fan, is variable, you can also install a Variable Frequency Drive (VFD) to save energy. Also called a variable speed drive (VSD), a VFD is an electronic device that controls the rotational speed of an AC motor by controlling the frequency of the electrical power supplied to the motor.

A VFD can save up to 75% of energy use, depending of the variation of the load.

It is important to note that if your pump, fan, motor, or aerator is operating continuously at the same load, the VFD will not save energy.

Motor Soft Starter

A soft starter is a device that temporarily reduces the load and torque of the electricity surge on the motor during start-up. It can be used with an AC electrical motor. The soft starter reduces electric and mechanical stresses on the motor and attached cables. By reducing these stresses, motor soft starters can lead to a longer system lifespan.